Fly Ash

|

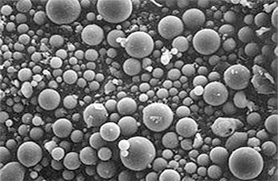

The combustion of pulverised coal at high temperatures and pressures in power stations produces different types of ash. The 'fine' ash fraction is carried upwards with the flue gases and captured before reaching the atmosphere by highly efficient electro static precipitators. This material is known as Pulverised Fuel Ash (PFA) or 'fly ash'. It is composed mainly of extremely fine, glassy spheres and looks similar to cement. It is a natural by Product. | |

| The use of Flyash in construction has been established for decades. Applications range from providing the cementitious material in concrete, to use as a simple fill material or a lightweight aggregate in the manufacture of blocks. Using Flyash makes a positive contribution to the environment. Flyash used in many applications to replace naturally occurring aggregates and minerals, which can reduce significantly the demand for virgin aggregates. | ||

AAC Blocks

|

AAC Blocks Description |

Sunla

|

Sunla Description |

Gypsum Powder

|

Gypsum Powder Description |

Silica Sand

|

Silica Sand Description |

Chicken Mess

|

Chicken Mess Description |

Metakaolin

|

Metakaolin is a dehydroxylated form of the clay mineral kaolinite. Metakaolin is a valuable admixture for concrete/cement applications. Rocks that are rich in kaolinite are known as china clay or kaolin, traditionally used in the manufacture of porcelain. The particle size of metakaolin is smaller than cement particles, but not as fine as silica fume. | |

| Calcium hydroxide accounts for up to 25% of the hydrated Portland cement, and calcium hydroxide does not contribute to the concrete's strength or durability. Metakaolin combines with the calcium hydroxide to produce additional cementing compounds, the material responsible for holding concrete together. Less calcium hydroxide and more cementing compounds means stronger concrete. Our experience has shown that optimal performance is achieved by replacing 10% to 15% of the cement with metakaolin. While it is possible to use less, the benefits are not fully realized until at least 10% metakaolin is used. The advantage of replacing some of the cement with metakaolin, rather than simply adding metakaolin to the mix, is that any existing color formulas or mix designs won't change, or will only very slightly change. This is because the dosage of pigments and superplasticizers are based on the cement content in the concrete. | ||

Concrete Blocks

|

Concrete Blocks Description |

Pozzocon

|

Pozzocon 40 is a high efficiency pozzolanic material, obtained by

selection and processing of power station fly ashes resulting from the

combustion of pulverised bituminous coal. Pozzocon 40 is subjected to

strict quality control. Retention 25-30% on 45 microns sieve.

Pozzocon 60 is a high efficiency pozzolanic material, obtained by selection and processing of power station fly ashes resulting from the combustion of pulverised bituminous coal. Pozzocon 60 is subjected to strict quality control. Retention 20-25% on 45 microns sieve. Pozzocon 80 is a high efficiency pozzolanic material, obtained by selection and processing of power station fly ashes resulting from the combustion of pulverised bituminous coal. Pozzocon 60 is subjected to strict quality control. Retention 16-18% on 45 microns sieve. Pozzocon 100 is a superfine processed fly ash designed for application in high performance concrete. The fineness specifications of Pozzocon 100 are stated below. Retention 0-1% on 45 Microns sieve. Specific Surface Area – 600 m2/kg, min Generally, the use of additives like microsilica is the most common practice for high performance concrete (more than 60 Mpa). The following set of trails illustrate the results of comparative concrete trial mixes done with 500 kg, 450 kg and 400 kg cement content with Pozzocon 100 against microsilica mixes. |

Cenosphere

|

Cenospheres are unique free flowing powders composed of hard shelled, hollow, minute spheres. A small proportion of the pulverized fuel ash (PFA) produced from the combustion of coal in power stations is formed as Cenospheres. Cenospheres are made up of Silica, Iron and alumina. Cenospheres have a size range from 1 to 500 microns with an average compressive strength of 3000+ psi. Colors range from white to dark gray. They are also referred to as microspheres, hollow spheres, hollow ceramic microspheres, micro balloons or glass beads or Floating Ash. | |